- Home

- Cellastim S – Reconstitution Application Note

Cellastim S – Reconstitution Application Note

Published on 17 September 2020

Marcus Curl, Director, Product Applications

Workflow Summary:

Human serum albumin (HSA) has been identified as a powerful tool for the expansion of many cell types in vitro [1]. HSA is a multifaceted protein capable of binding many different types of molecules [2]. HSA therefore plays diverse roles in cell biology, acting as an antioxidant to improve health of cells by binding to reactive oxygen species, as an energy-delivery system by chaperoning fatty acids in the bloodstream, and as a mediator for solubilization and stabilization of metal ions required for cellular processes [2,3]. These functions make HSA supplementation of cell culture media an integral step in facilitating cell growth and expansion in vitro, particularly when removing serum or blood-derived proteins for use in clinical manufacturing. Using Cellastim S as a recombinant and scalable source of albumin in cell culture is an enabling tool for large-scale manufacture of cell-based and gene therapies. It is the goal of this app note to provide a step-by-step overview for preparing Cellastim S for use as a stock liquid solution for in vitro cell culture applications.

Introduction:

Human serum albumin (HSA) has been identified as a powerful tool for the expansion of many cell types in vitro [1]. HSA is a multifaceted protein capable of binding many different types of molecules [2]. HSA therefore plays diverse roles in cell biology, acting as an antioxidant to improve health of cells by binding to reactive oxygen species, as an energy-delivery system by chaperoning fatty acids in the bloodstream, and as a mediator for solubilization and stabilization of metal ions required for cellular processes [2,3]. These functions make HSA supplementation of cell culture media an integral step in facilitating cell growth and expansion in vitro, particularly when removing serum or blood-derived proteins for use in clinical manufacturing.

As cell-based immunotherapies, gene therapies, and stem cell therapies continue to show promise in the lab and in the clinic [4–6], the availability of safe and consistently high-performing HSA grows in importance for the future of these technologies [7]. Currently HSA used in the expansion of mesenchymal stem cells (MSC), hematopoietic stem cells (HSC), T Cells, HEK293, VERO, MDCK, BHK-21, and many other key cell types is sourced directly from human serum [1,8]. This albumin source has been instrumental to the conception and development of these novel therapeutics. However, supplementation of cell-culture growth media with serum-derived media supplements and other animal-derived components can introduce adventitious pathogenic agents, create variability when cell expansion processes are scaled up for clinical manufacturing, and can also present the risk of a supply-chain bottleneck. Accordingly, chemically defined media, supplemented with recombinant and well-characterized alternatives to animal-derived components, is increasingly being used as a viable strategy for reducing variation, improving consistency, and enabling scalability for cell-based therapies [7,9].

Cellastim S is a completely blood-free and animal-free human albumin produced in a scalable, non-mammalian recombinant expression system. It is naturally free of prion agents (bovine spongiform encephalopathy and other transmissible spongiform encephalopathy agents), and carries less potential risk from other mammalian adventitious agents compared to serum-derived components. In addition to improved safety, Cellastim S has shown consistent performance in supporting the culture of T-Lymphocytes, HEK293, MSC, HSC, and VERO, among other cell types [10,11]. Using Cellastim S as a recombinant and scalable source of albumin in cell culture is an enabling tool for large-scale manufacture of cell-based and gene therapies. It is the goal of this app note to provide a step-by-step overview for preparing Cellastim S for use as a stock liquid solution for in vitro cell culture applications.

Materials Needed:

Recombinant Human Serum Albumin

- Cellastim S (InVitria 777HSA017S)

Reconstitution Supplies

- 125 ml sterile PETG media bottle (ThermoFisher 2019-0125)

- Cell culture grade DPBS, PBS, or basal media such as DMEM F/12, DMEM, MEM, RPMI

Vacuum Filtration System

- 500 ml 0.2 micron vacuum filtration system (Millipore SCGPU05RE)

Protocol:

Cellastim/Cellastim S Stock Preparation

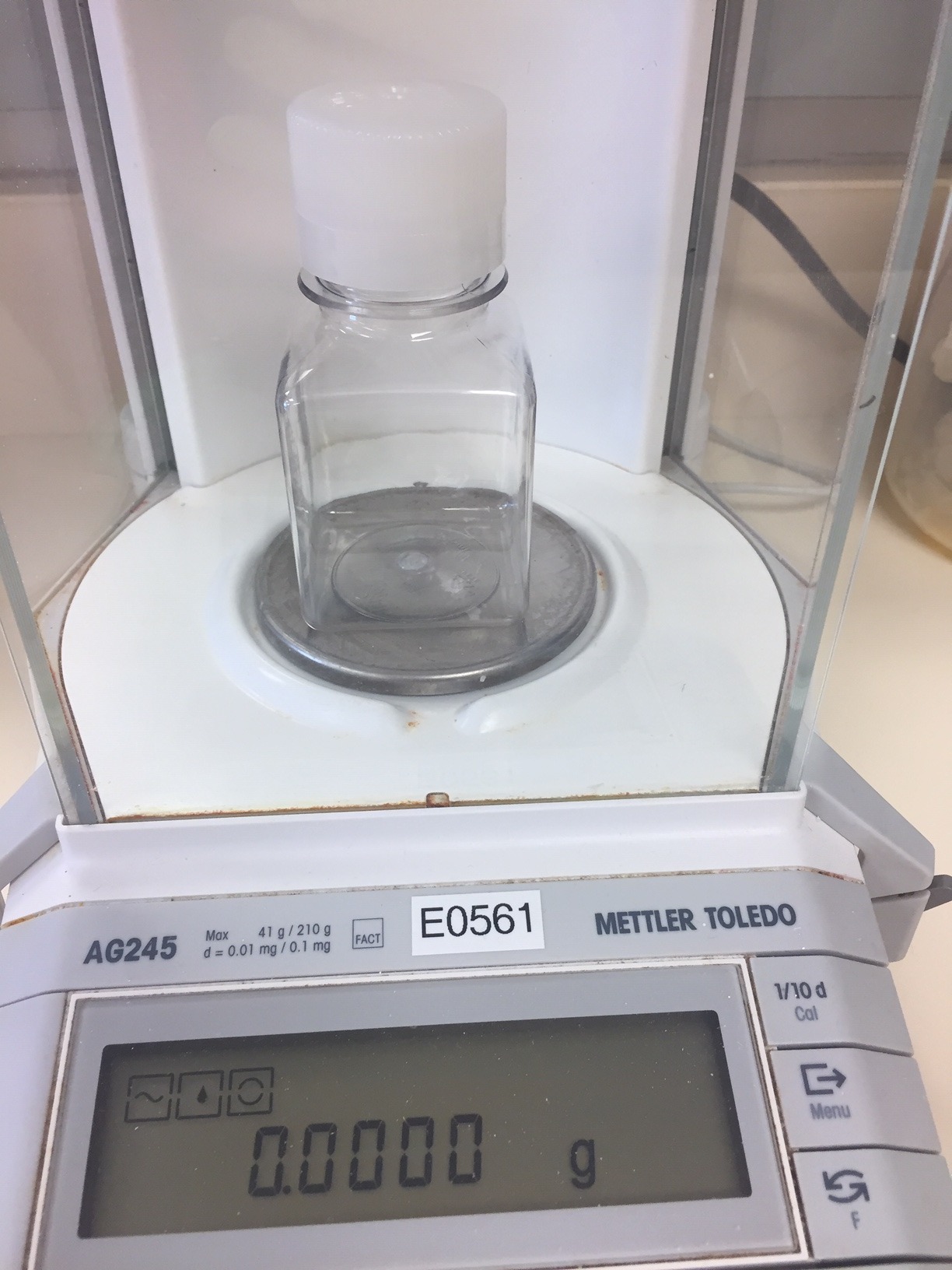

To prepare a sterile, 10% concentrated liquid stock solution of Cellastim S, first weigh an empty, 125 ml Sterile PETG Media Bottle.

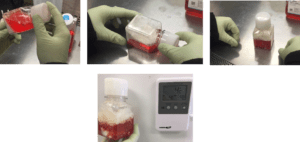

Under a laminar flow hood, add 10 g Cellastim S to the bottle. Weigh the bottle containing the powder to determine the actual weight of Cellastim S added.

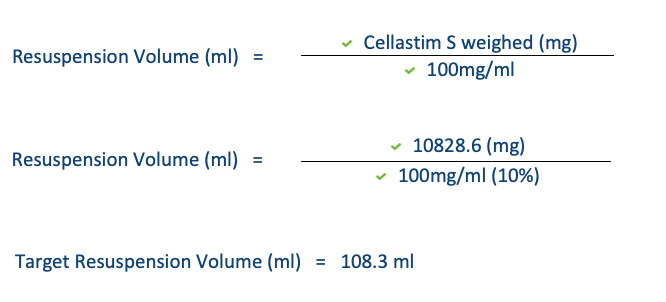

Once the exact weight of Cellastim S is known, calculate the volume required to produce a 10% concentration of Cellastim S. Then, gently reconstitute the powder in cell-culture grade DPBS, PBS, or the selected basal media by adding 70% of the calculated final volume directly to the 125 ml bottle. Do not add the full final volume of buffer at this stage. An allowance must be made to account for volume displacement caused by the powder.

Cap the 125 ml bottle and gently turn it on its side to allow the powdered albumin to fall into the buffer. Avoid the formation of bubbles during this step. Return the container upright and allow the albumin to dissolve, undisturbed (no shaking) at 4°C in the dark for a minimum of 4 hours and preferably overnight.

Once all the powdered Cellastim S has dissolved, bring the volume up to the calculated target by adding additional reconstitution liquid. To achieve this easily, use a 50 ml pipette to move exactly 50 ml of the reconstituted albumin powder to a fresh 125 ml bottle. Using the same pipette, remove the remaining liquid from the original bottle, noting the volume. Finally, pipet the difference between the target volume and the volume as measured by pipetting, and add this volume of reconstitution liquid to the new bottle.

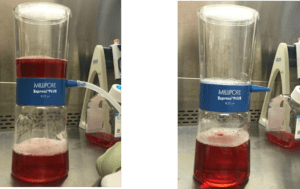

Sterilize the stock solution by filtering through an 0.2 µm vacuum-driven disposable filtration system.

Optional: For manual filtration, InVitria recommends using a 25 mm, 0.8 µm filter (Pall 4188), followed by a 0.2 µm 30mm PES low-protein-binding filter (Celltreat 229747), using a sterile Luer-lock syringe (Medline SYR103010H).

Example Calculations

The following content is gated. Please, subscribe to open access to it.

Footnotes

- Francis GL. Albumin and mammalian cell culture: implications for biotechnology applications. Cytotechnology. 2010;62(1):1-16. https://doi.org/10.1007/s10616-010-9263-3

- He XM, Carter DC. Atomic structure and chemistry of human serum albumin. Nature. 1992;358(6383):209-215. https://doi.org/10.1038/358209a0

- Taverna M, Marie AL, Mira JP, Guidet B. Specific antioxidant properties of human serum albumin. Ann Intensive Care. 2013;3(1):4. https://doi.org/10.1186/2110-5820-3-4

- Maude SL, Teachey DT, Porter DL, Grupp SA. CD19-targeted chimeric antigen receptor T-cell therapy for acute lymphoblastic leukemia. Blood. 2015;125(26):4017-4023. https://doi.org/10.1182/blood-2014-12-580068

- Trounson A, Thakar RG, Lomax G, Gibbons D. Clinical trials for stem cell therapies. BMC Med. 2011;9:52. https://doi.org/10.1186/1741-7015-9-52

- Cavazzana-Calvo M, Hacein-Bey S, de Saint Basile G et al. Gene therapy of human severe combined immunodeficiency (SCID)-X1 disease. Science. 2000;288(5466):669-672.

- van der Valk J, Brunner D, De Smet K et al. Optimization of chemically defined cell culture media–replacing fetal bovine serum in mammalian in vitro methods. Toxicol In Vitro. 2010;24(4):1053-1063. https://doi.org/10.1016/j.tiv.2010.03.016

- Blázquez-Prunera A, Díez JM, Gajardo R, Grancha S. Human mesenchymal stem cells maintain their phenotype, multipotentiality, and genetic stability when cultured using a defined xeno-free human plasma fraction. Stem Cell Res Ther. 2017;8(1):103. https://doi.org/10.1186/s13287-017-0552-z

- Chisini LA, Conde MCM, Grazioli G et al. Venous Blood Derivatives as FBS-Substitutes for Mesenchymal Stem Cells: A Systematic Scoping Review. Braz Dent J. 2017;28(6):657-668. https://doi.org/10.1590/0103-6440201701646

- Alfano RW. Albumin in cell culture media—an examination of quality and function. In: Brieva T, Miller W, Mason C, eds. Scale-up and manufacturing of cell-based therapies V. ECI Symposium Series; 2017 https://dc.engconfintl.org/cellbasedtherapies_v/22

- Pennybaker A, Alfano R. Utilization of recombinant albumins in the expansion of human T lymphocytes. Cell Gene Ther Insights. 2018;4(4):231-239.